| South Africa used clear view fence for house protection on sale |

>>>>>>Click here for more types. >>>>>>Click here for more types.

|

>>>>>>Contact us for further information.

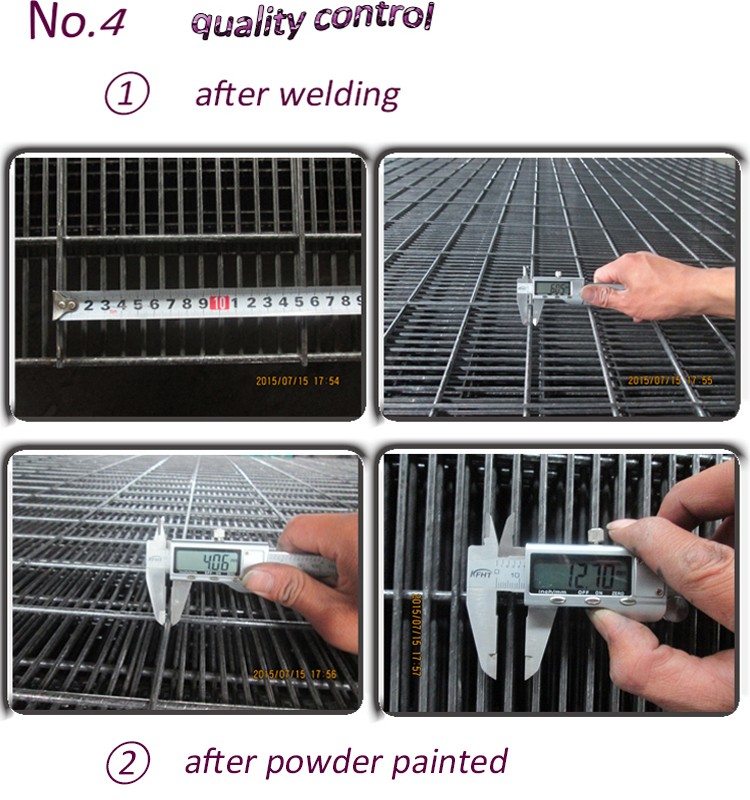

We adopt the most advanced spot welding machines, after welding the panel's surface will be flat and high tensile strength. For panels we can reach the smallest error: Wire Diameter:±0.03mm

Mesh Opening:±1.0mm

Panel Length & Width:±3.0mm Diagonal Line:±4.0mm

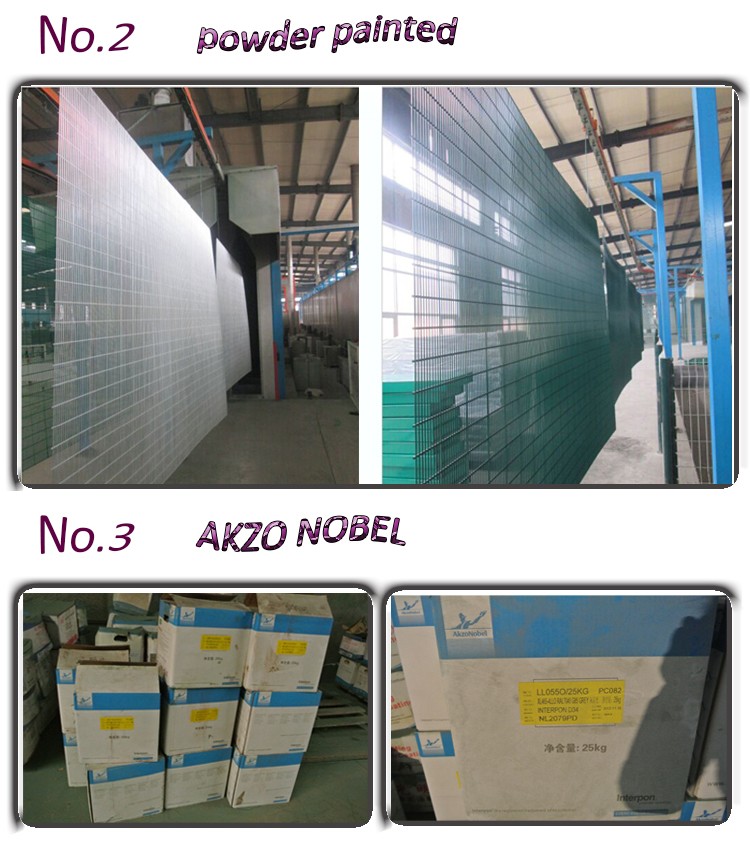

We have the most advanced and expensive fullautomatic production line. (only a spray gun costs RMB30000.00). After painting,the finished panels looks very glossy and bright. Theoretically the anti corrosion effect can be 15 years. We use imported powder AKZO NOBEL, which has good adhesive force.

General we have 3 times quality control, after welding panel; after powder painted; before packing. The processes of quality control can pick out damaged products and guarantee the product quality.

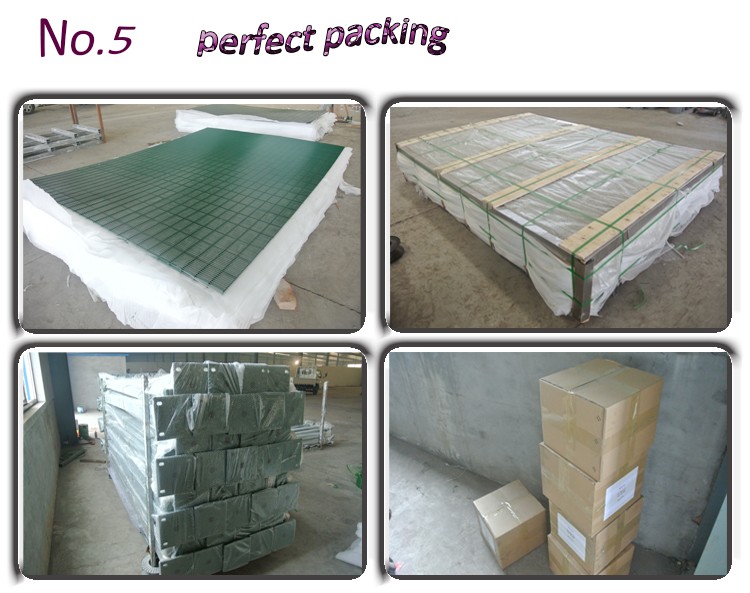

Panel packing (1) Bubble wrap at the bottom of pallet, which can protect the last panel (2)Putting plastic film between each two panels to prevent rubbing against each other (3) Metal corners fixed at each corner of the panels, which can keep the panels stay together and immovable. (4)The wood panels on the panels can prevent the last panel destroyed by other pallets. Post packing: Plastic film+pallet Accessories packing: Accessories will be packed by small plastic bags and carton box. >>>>>> Contact us. |

|

|